Leistritz L2 screw pumps are self-priming, positive displacement pumps that go to a pressure range of up to 250 psi. This is suitable for transporting fluids that are light abrasive, corrosive, high viscous, or low viscous. The fluid can have either poor or good lubricity.

L2 Series Screw Pumps

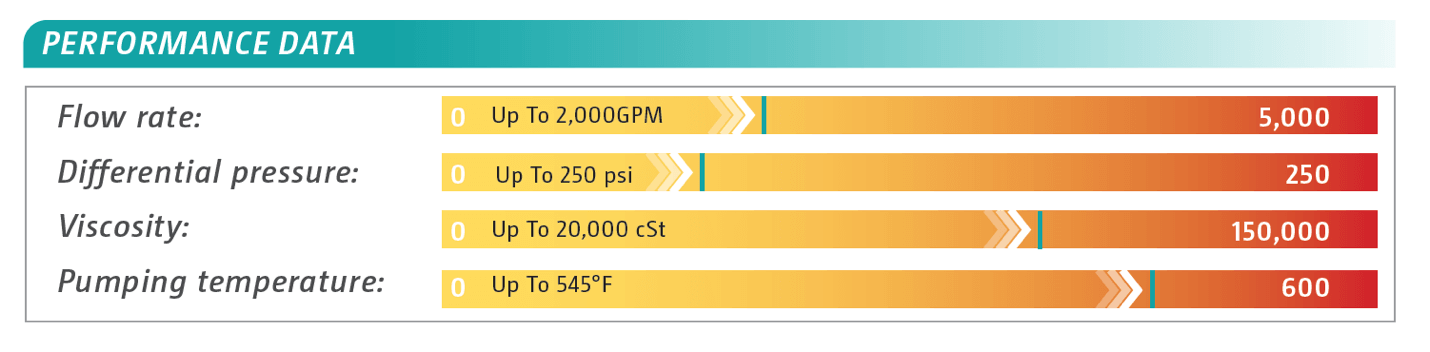

| Performance Data | |

|---|---|

| Flow Rate | 3 to 2,200 GPM |

| Viscosity | 2 to 100,000 cSt |

| Temperature | -40 to 545 Deg F |

| Applications |

|---|

| Asphalt & PMA |

| MDI & MDA |

| Lube Oil |

| Pitch & Tar |

| Bunker C & Heavy Fuel Oil |

| Diesel Oil & VGO |

The Right Screw Pump for Asphalt Applications

The L2 series of pumps are cost-effective, robust, efficient, and available from stock. There is a wide range of sizes to meet the demands of most applications in asphalt pumping.

Above-ground tank concepts at storage terminals are the basis of a reliable and cost-efficient distribution process. The characteristics of asphalt and related products require pumps that are designed to efficiently transfer and circulate the fluids, often with very challenging operating conditions.

The typical pumping scenario requires pumps to handle fluids with high temperature, high viscosity during cold start, entrainment of air and gas in the pump flow, solids and impurities, and slugs of cold product. This in combination with a continuous and reliable operation together with the demand for low energy and maintenance costs limits the choice of pump technology for the operator.

Leistritz screw pumps provide an optimum solution. They are used at asphalt terminals to move product between carriers and storage tanks. In comparison to other types of pumps, their exceptional suction capability allows faster unloading/transfer of asphalt.

Benefits

- Low Maintenance

- Save Energy

- Quiet, Pulsation-Free Operation

- Resistant to Plugs

- Excellent Suction Lift

- Competitive Price Point

- In-Stock*

- Increased Profitability

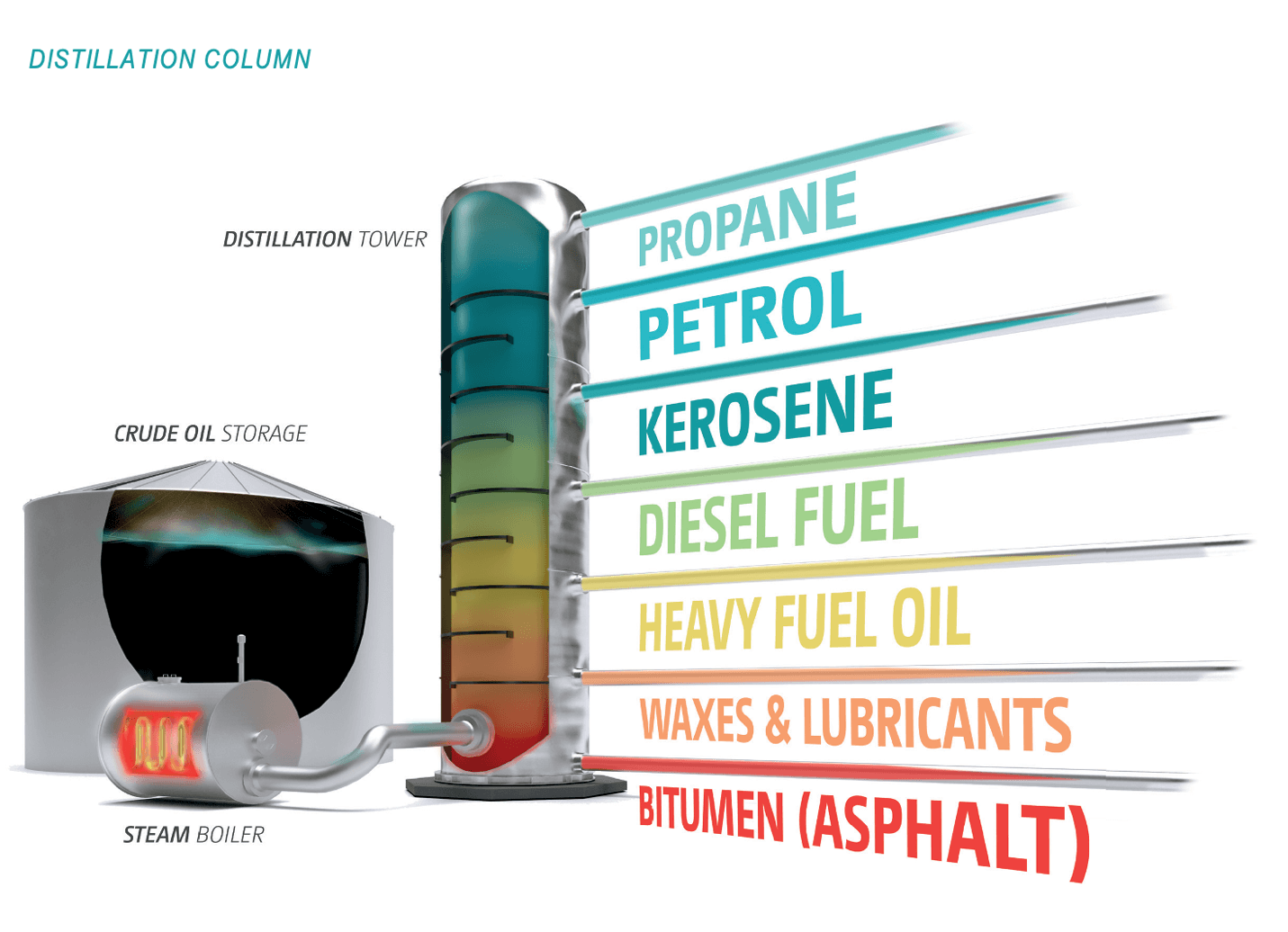

A Bit about Bitumen Production

During distillation, crude oil is heated to temperatures in order to separate the low-boiling point components from the non-boiling ones under atmospheric pressure. These lighter fractions are then removed and processed separately. What remains is atmospheric residuum. In order to ensure the complete removal of light fractions without thermal alteration of the molecular structure, the atmospheric residue is then transferred to vacuum distillation. At reduced pressure, the boiling points of the components drop and bitumen remains. The thickness and quality of the bitumen can be determined by pressure and temperature.

Bottom Line

Cut Your Maintenance Costs

L2 Pumps operate under cold conditions without breaking gear teeth or shafts. By design, the internal porting and screw profile handle slugs of cold asphalt without damaging the rotating elements. The integral relief valve lets operators manually re-circulate the asphalt internally. This allows for pumping cold slugs from the piping while eliminating the potential for broken shafts caused by over-pressurization.

Cut Your Operating Costs

The unique design and powerful suction capability of the Leistritz screw pumps pumps asphalt at temperatures as low as 250 F, which is at least 20 lower than other pumps. The result is less energy consumption, faster material handling, greater efficiency – all resulting in enormous cost savings.

L2 Specifications